Pressure vessels - Gas treatment process

The name Pressure vessels applies to all equipment intended for the production, manufacture, storage or application of vapor, compressed, liquefied or dissolved gas, at an above atmospheric pressure. Piping and safety accessories are also included in this category. All these equipments are designed with a maximum safety objective; taking into account the parameters of pressure, temperatures, and corrosion margin. The equipments are subjected to non-destructive testing (NDT), bleeding, ultrasonic testing, radiography and pressure testing.

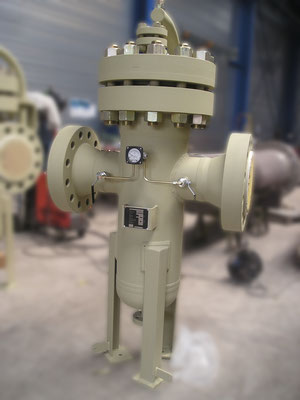

Gas filters

Gas filters are used to protect facilities against gas transported dust. They consist of the following elements:

- one or more filter cartridges

- a fast opening door or a full flange to access the cartridges

Sizing criteria’s:

- Gas flow

- Quantity of solids

- Pressure and temperature of service

- Efficiency required

- Load loss allocated

Options:

- Instrumentation

- Indicator of load loss

Other possible configurations:

- Vertical gas filters

- Horizontal gas filters

Separator filters

The separator filters protect the plants against gas transported liquid and solid particles. They consist of the following elements:

- a first level composed of filtering and coalescing cartridges to filter solid particles and the coalescence liquid droplets.

- a second level composed of a baffled block ensuring the separation of the liquid droplets.

- Holding capacity

- a fast opening door or a full flange to access the cartridges

Sizing criteria:

- Gas flow

- Quantity of liquids and solids to separate

- Pressure and temperature of service

- Efficiency required

- Allowance losses allocated

Options:

- Instrumentation

- Level indicator

- Indicator of load of loss

- Safety valve

Other possible arrangement:

- Horizontal separator filters

Horizontal separator filter

The separator filters protect the plants against gas transported liquid and solid particles. They consist of the following elements:

- a first level composed of filtering and coalescing cartridges to filter solid particles and the coalescence liquid droplets.

- a second level composed of a baffled block ensuring the separation of the liquid droplets.

- Holding capacity

- a fast opening door or a full flange to access the cartridges

Sizing criteria:

- Gas flow

- Quantity of liquids and solids to separate

- Pressure and temperature of service

- Efficiency required

- Allowance losses allocated

Options:

- Instrumentation

- Level indicator

- Indicator of load of loss

- Safety valve

Other possible arrangement:

- Vertical separating filters

Baffled separators

The baffled separators allow to separate the liquids (droplets) from the gases. They come in different configurations depending on the amount of liquid to be separated.

They consist of the following elements:

- tubing with different types of deflectors

- a baffle block with a support box

- a retention capacity

Sizing criteria:

- Gas flow

- Quantity of liquids to separate

- Pressure and temperature of service

- Efficiency required

Load loss allocated

options:

- Instrumentation

- Level indicator

- Load loss indicator

- Safety valve

Cyclone searators

Cyclone separators allow to separate liquid and solid particles present in the gas. They come in different configurations depending on the amount to be separated. They have the advantage of not clogging while admitting large amounts of particles to separate.

They consist of the following elements:

- a set of cyclone tubes

- retention capacity

Sizing criteria:

- Gas flow

- Quantity of solid and liquid particles to separate

- Pressure and temperature of service

- Efficiency required

- load loss allocated

Options

- Instrumentation

- Level indicator

- Indicator of load loss

- Safety valve

Pig traps

A Pig Trap is a pressure vessel. If installed at the ends of a pipeline allows the sending and reception of pistons used to clean the inside of the piping by scraping.

It can be connected by welds or flanges (mobile wiper station).

Our pig traps are equipped with a tubular body of connection to your pipeline, a truncated cone, a tubular body (lock) allowing the sending and the reception of the piston and a system of closure by flanges (pipe Ø < to DN300) or quick-closure type cylinder head PC (pipe Ø > or = to DN300).

FILTRES EQUIPEMENTS’ closing heads are qualified by GRTgaz and can be equipped with a centralized opening and closing system for large dimensions.

We study and manufacture pig traps according to our clients standards and dimensions (with on-site visits).

Our pig traps can be equipped with optional accessories:

- Passing indicator

- Faucet (Purge, vent ...)

- instrumentations

- Various taps (balancing, methanol injection ...)

Skids

FILTRES EQUIPEMENTS produces Skids in accordance with customer specifications. We are able to provide you with the most suitable solution such as: the study of specifications, design and manufacturing solution. A skid such as filtration, gas expansion bench etc. is a ready-to-use solution that meets the needs expressed by our customers in many sectors of activity.

A Skid can be composed of static filters, Pig traps, pumps, valves, probes, pressure gauges... The filter bodies can be standard but also custom-made (double jacket, high pressure...) as well as expansion and gas heating units.

We also provide the power supply for the devices used to monitor important physical parameters. All our Skids are delivered ready-to-use according to customer requests.

Degassers

The degassers allows to recover the liquids brought by the gas during the venting of a pressure vessel.

The number and the nominal diameter of the connection pipes are specified by the customer.

Sizing criteria:

- Max flow rate in Nm3 / h

- Pressure upstream of the trigger

- Diameter and number of connections

The degasser consists of the following elements:

- Entrance deflector

- Separating element

- Retention capacity

- Anti-Vortex on the purge tubing

- Firewall end of line or online

- Disc rupture with burst contact

According to customer specifications, the degasser can be equipped with the following instruments:

- Visible level with contacts

- Level detector

- manometer

- Pressure transmitter

Tanks & pressure vessels

A tank is a pressurized equipment used to store a fluid (gas or liquid) without a fluid transformation operation (filtration, reheating ...).

Our fabrications can be applied in many industrial fields for both gas and liquids.

FILTRES EQUIPEMENTS studies, sizes and manufactures tanks according to the clients’ needs and specifications, and in compliance with the regulations PED 2014/68 / EU (decree 2015-799).

We rely on recognized building codes such as: CODAP, ASME, AD MERKBLATTER.

Our material and human resources enable us to build high capacity tanks (> 55 m3), in both black or stainless steels.

The tanks are equipped with a main body (tube or shell rolled / welded) closed by 2 bottoms (elliptical, GRC, flat bottom ...)

Our tanks can be equipped with optional accessories:

- Gauges

- Faucet (Purge, vent ...)

- instrumentations

- Various tapping (look, hand hole, manhole ...)

Vent silencers

Silencers are intended to reduce the noise generated by the vent to the pressurized gas and steam’s atmosphere.

They feature three main sections:

- the inlet diffuser designed to withstand the full impact of the pressure expansion and the incoming fluid. It provides a shift of low frequencies to the more easily attenuated high frequencies bands.

- the plenum chambers

- the splitter panels reduce the noise level to the required value.

Typical Application:

- Safety Relief Valves.

- Steam, Air and Gas Vents.

- Process Gas Blowdown.

- Boiler Start-Up and Purge.

Performances

- The vents silencers are designed to meet the specified silenced noise level at a given distance.

- The diffuser can be designed to provide the required pressure.

Sizing Criteria

- Flow rate and density of gas.

- Valve pressure and upstream temperature.

- Required silenced noise level at distance.

Electric heater filter

They combine the filter function and heater and are most often installed upstream of an expansion valve.

They can be installed at the location of existing cartridge filters without having to change the piping layout.

Heating is provided by one or two immersion heaters mounted on the filter body and whose power is chosen according to the operating conditions.

They consist of the following elements:

- a cartridge filter

- one or two immersion heaters

- temperature sensors

- a control cabinet

Sizing criteria:

- Gas flow

- Upstream and downstream service pressures

- Inlet temperature

- Required temperature downstream of the trigger

Bain-marie heater (RBE)

It allows the natural gas passing through a pipeline to be warmed without making any major changes to the route of the pipeline. It has the advantage of being autonomous in energy, the necessary fuel gas being taken from the installation.

They consist of the following elements:

- hot water tank

- coil dipping in hot water

- burner with its smoke tubes

- range of fuel gas supply

- control cabinet

- temperature sensors

- various instruments necessary for regulation

Sizing criteria:

- Gas flow

- Operating pressure

- Inlet and outlet temperature

- Desired power

Main configurations:

- Diameter of the pipe: from DN50 to DN200

- Available power range 50 to 300 kW